Oiling the action - for geeks

Since the original article on Oiling

The Action was published I've had a few emails from repairers

and seen references on various web sites which claim that this method

of oiling the action is ineffective.

This has always surprised me, given that my standard 'lecture

to a lazy client' involves placing a drop of oil at each end of

a rattly key's barrel and then working the key as the oil wicks

in. It's an effective demonstration, as both the client and I can

hear the rattles fade away as the oil does its work.

But it's been suggested that the oil is only getting part-way into

the barrel (if at all) - so I put my 'myth-buster' hat on and set

up a small experiment.

I approached the project with an open mind - I was pretty sure that

the visible results would match my hands-on experience, but I was

more than prepared to accept being proved wrong. As it turns out,

I found out more than I bargained for...

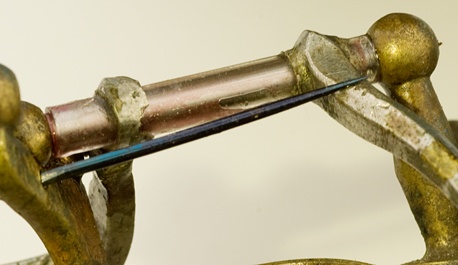

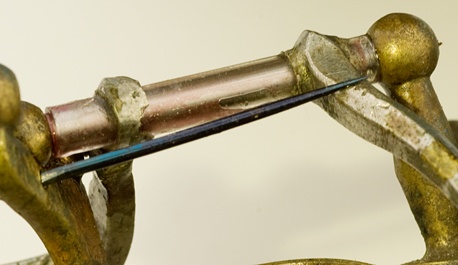

I

dug out an old 'beater' sax, cut the key arms off the G# key and

replaced the barrel with a stiff acrylic tube. I then made and fitted

a rod screw, and just to make it a tough test I made sure the rod

screw was a very snug fit. I glued the key arms in place and fitted

a spring - with no spring cradle on the key I simply ran the spring

over the top of the link arm (which rests on the G# key cup arm). I

dug out an old 'beater' sax, cut the key arms off the G# key and

replaced the barrel with a stiff acrylic tube. I then made and fitted

a rod screw, and just to make it a tough test I made sure the rod

screw was a very snug fit. I glued the key arms in place and fitted

a spring - with no spring cradle on the key I simply ran the spring

over the top of the link arm (which rests on the G# key cup arm).

To make it an even tougher test I laid the sax at the angle shown

in the photos rather than stand it upright - and finally, just to

make it interesting, I used some old gear oil (I figured the black

oil would show up better)...with around twice the viscosity I'd

normally recommend.

So, we have a well-fitting pivot screw in a wear-free barrel, a

shallow angle and some very heavy oil. At this point I was wondering

whether I'd overcooked it, but what the hell - the experiment was

set to go and all that was needed was a couple of drops of oil.

The sequence runs left-to-right, top to bottom.

You can see the oil that's just been applied in the first shot (top

left) - and here's the really odd thing...I'd set a timer going,

and having applied the oil I turned away briefly to make a note

of the time - and when I turned back a few seconds later I saw what

you can see top right. In a matter of mere seconds the oil has wicked

about a third of the way in from each end. Even more interestingly,

the oil on the lower pillar has wicked upwards. This will be due

to capillary action - in effect the oil is being sucked into the

barrel.

This kind of knackered my test a bit, I'd made plans to operate

the G# lever against the clock and take photos at specific intervals

so that I could present a posh-looking graph showing ingress of

oil against time - and while I was busy cursing and damning, the

oil met in the middle of the barrel (lower left).

I felt a bit left out now, so I gave the G# lever a few presses

- and about 10 seconds later I noted that the oil had completely

filled the barrel. The whole sequence of photos covers barely a

couple of minutes.

So what can be deduced from the test?

Well, the most obvious point is that popping a drop of oil at each

end of a key barrel is going to result in oil getting where it's

supposed to go - even when the odds are stacked against it. Personally

I'm quite surprised at the speed of the coverage (and, incidentally,

it's even faster if there's a bit of wear in the barrel - I tested

that too), as well as the ease with which such a heavy oil wicked

into the barrel.

Another interesting outcome is the clear importance of giving the

pillars a bit of a wipe-over with a tissue after oiling - even with

such a heavy oil you can just see (on the lower pillar) where it's

starting to make its way down the pillar.

A certain amount of oil seems to remain in a 'pool' around the ends

of the key barrel. Some of this eventually migrates away down the

pillar (which is why you need to re-oil the action from time to

time), but equally some of it gets sucked back into the barrel as

the key is operated.

For most readers with a slightly geeky predilection, this is all

you need to know - and at this point you should turn your computer

off and go do some practice (or have a beer or three).

For the advanced nerds, however, there's more...

With the oil inside a see-through barrel I was able to observe

how it moved about when the key was pressed. In both cases (with

the tight and loose barrels) it was plain to see that the flex of

the key barrel (and there will always be some) acts like a pump,

distributing oil around and along the barrel. What was most revealing

was that the pivot screw is not fully lubricated all of the time.

For example, as this particular key is pushed down the barrel flexes

and oil is pushed away from the upper rear surface of the pivot.

As the key is released the barrel relaxes and oil is sucked back

in to the void. The effect is just as noticeable on a worn barrel

- but rather surprisingly the amount of unlubricated surface area

is less, due to the less-effective pumping action as a result of

the wear in the barrel. There seems to be a 'break-point' though...a

small amount of free play seems to increase the pumping action,

but once it gets beyond a certain point it allows the oil to slosh

around more liberally. It's also the case that the harder you press

the keys, the stronger the pumping action - so heavy-handed players

should perhaps oil the action more frequently.

Furthermore, the areas affected by the tension of the spring when

the key is at rest (the point where the tip of the spring acts against

the barrel and the end of the key nearest the mounting point of

the spring) are more-or-less devoid of oil.

This

phenomenon was more evident with a thinner oil. Here I've mixed

some black oil with a bit of typically thin shop-bought key oil.

The pumping action was rather more rapid and widespread, and there

was far less evidence of the pooling effect at the end of the key

barrels. In short, the oil was simply being ejected from the key

barrel. This

phenomenon was more evident with a thinner oil. Here I've mixed

some black oil with a bit of typically thin shop-bought key oil.

The pumping action was rather more rapid and widespread, and there

was far less evidence of the pooling effect at the end of the key

barrels. In short, the oil was simply being ejected from the key

barrel.

As you can see on the left here, with the key at rest (top) there

is complete coverage of the pivot screw by the thin oil - but as

soon as the key is pressed, the oil is pushed away from the rear

of the key over almost the entire length of the barrel. This effect

is less widespread with a thicker oil.

This caused me to wonder whether grease would be a far better lubricant,

so I tried it - and it is...but not for long.

The same pumping action is in evidence - though rather than being

a fluid (ho ho) action it's more of an accumulative one. It seems

to be unequal too - there's clearly a stronger pushing force than

there is a suction one, which means that once the grease has been

pushed away from a particular area, it doesn't get sucked back.

In short, the pivot screw has to 'wait' until such time as the grease

is pushed into an adjacent space - at which point it might then

get pushed into the dry spot. And then the cycle repeats. It has

little or none of the 'recovery flow' patterns that oil has - whereby

it flows into dry spot when the key is at rest - and from a purely

observational perspective it's apparent that a greased pivot screw

has more dry spots than an oiled one.

One way around this problem is to use thicker, stickier grease -which

I tried - but the required stickiness is such that the action of

the key is severely affected, and the instrument never gets to the

sort of temperatures where a grease would become thin enough to

be an effective lubricant.

So what does this all mean?

My feeling is that it's very much a case of "Damned if you

do, damned if you don't".

It should at least be very clear that there's some sort of 'peristaltic'

action going on, and that stripping an action solely to oil

it is arguably a complete waste of time (unless you clean/degrease

it at the same time). You simply can't get more oil into a key barrel

once it's full, and what determines the distribution of the oil

is not how much you put on but how it's pushed around inside the

barrel by the pumping action of the key barrel. The two images above

demonstrate that clearly - the key was pre-oiled before assembly.

It's clear too that the thicker the lubricant, the more effective

it's going to be - but only up to a point. Once it gets too thick

it becomes rather less good at its job due to its poor 'recovery'

rate - and beyond that it will have a detrimental effect on the

speed of the action. It's also very evident that a thin lubricant

really isn't much use at all - and that the tighter and more precise

the action, the higher the peristaltic pressure will be (though

a smaller volume of oil will be shifted - but it will be shifted

further, and faster).

To be sure, the stiffness of the barrel plays a major part in the

mechanics - but the tubing used for the experiment was pretty stiff

stuff, and although I wouldn't expect the effects within a similarly-sized

brass key barrel to be as severe, I still wouldn't dismiss the accumulative

effects - and once you introduce the slightest amount of wear into

the equation the pump-effect ramps up, at least until such times

as the wear becomes so great as to negate it.

And so it's easy to conclude that if you want to avoid wear and

tear to the action - buy a worn-out horn and slap a load of light

grease on it.

Update January 2019:

Some time ago I made the mistake of putting synthetic gear oil

onto a rod screw that I'd earlier lubricated with silicone grease

(as detailed in a

Benchlife Blog entry). I noticed that the addition of the oil

made a noticeable difference to the speed with which the key operated.

This is exactly what you'd expect, given that the oil altered the

viscosity of the grease and produced a thinner lubricant.

This got me wondering whether the two lubricants were incompatible

in any way. If it turned out that they reacted with each other in

some fashion, it might mean that, say, the mixture would congeal

over time and eventually slow the action down - which would not

be good. So I set up a series of tests to see what was going on

- and the results surprised me.

The

grease is bog-standard high tack (HT) silicone grease and the oil

is 75W90 synthetic gear oil (as shown in the article on Oiling

The Action), and the first test was to mix the two lubricants

together to see what happens. The

grease is bog-standard high tack (HT) silicone grease and the oil

is 75W90 synthetic gear oil (as shown in the article on Oiling

The Action), and the first test was to mix the two lubricants

together to see what happens.

I stuck an adhesive tack bung on the bottom of a perspex tube, popped

a dollop of grease into the tube and then added a quantity of gear

oil - and gave it all a good stir.

The lubricants appeared to blend together to form a milky goo. At

first glance it looked like they'd properly blended, but on close

inspection I saw that the oil had broken down into minute bubbles.

What I'd made was an emulsion - one liquid suspended within another.

This is what emulsion paint is, and it's also what your salad dressing

is (a mixture of oil and vinegar).

Emulsions

have a tendency to separate over a period of time - hence the 'stir

well before use' warning on pot of emulsion paint and the 'shake

well before use' on a bottle of salad dressing - so I left the tube

standing, to see whether or not the lubes would separate and, if

so, how quickly. Emulsions

have a tendency to separate over a period of time - hence the 'stir

well before use' warning on pot of emulsion paint and the 'shake

well before use' on a bottle of salad dressing - so I left the tube

standing, to see whether or not the lubes would separate and, if

so, how quickly.

It didn't take long. Separation was evident within the first hour,

with a clear film of oil forming on top of the mixture. Over the

next couple of days the oil rose to the top of the mix until the

film became a clearly visible band - but it took a good couple of

weeks before all the oil had risen to the top and a very clear boundary

between the oil and the grease could be seen.

I re-stirred the mixture and left it to stand again - and repeated

the test a number of times, and in each case the oil eventually

rose to the top.

It seems clear then that there's no reaction between the two lubricants

and even heating the mix made little difference (other than to speed

up the rate of separation), so it appears that they'll quite happily

co-exist with each other and won't combine without some sort of

mechanical intervention.

And it's this property that raises an interesting question. My tests

with the transparent key barrel showed that there were pros and

cons depending on which lubricant was used - but could an emulsion

of oil and grease overcome the cons? Would it be the best of both

worlds, so to speak? Only one way to find out - and that's by putting

it to the test.

I

began by testing how the silicone grease performs on its own inside

a key barrel. I

began by testing how the silicone grease performs on its own inside

a key barrel.

In order to give it the best chance I made sure I got as much grease

as possible into the barrel, but as expected it pretty much just

stays put. The pumping action of the barrel when the key is operated

will move the grease away from the areas where it's most needed,

and when the key is released the grease is reluctant to move back.

It can be quite hard to see what's going on, but fortunately there'll

always be a few air bubbles that will act as indicators. You can

just about see them in the centre of the barrel, and with each operation

of the key they'll move back and forth very slightly. You might

also be able to see a dark line running either side (parallel with

the spring) of the first key arm, which is the beginnings of an

area where the grease will be pushed away from over time (a wear

point, in other words).

Now I've dripped some gear oil (dyed red) onto one end of the key

barrel. I'm interested in seeing whether the pumping action will

still work - or whether the grease shuts the process down.

The

result is very encouraging. With only a few presses of the key you

can see that the oil and been drawn around a quarter of the way

into the barrel, and is just starting to make its way past the first

key arm. And it's travelling uphill. The

result is very encouraging. With only a few presses of the key you

can see that the oil and been drawn around a quarter of the way

into the barrel, and is just starting to make its way past the first

key arm. And it's travelling uphill.

It eventually got to the other end of the key, but it took rather

longer than it would had oil alone been used. Normally you'd apply

the oil at each end of the barrel...but I like to make these tests

hard.

This tells me that even when the barrel is initially filled with

grease, operating the key will create voids that oil can flow in

to. This means a greased key can be further lubricated with oil

without having to remove the key - which is a considerable plus-point

in maintenance terms. It also means that when you're assembling

a horn you can run a greased rod screw through a key barrel and

then apply oil to the rod just prior to fitting the key. In other

words there's no need to premix the oil and the grease.

For

the final test I premixed a batch of oil and grease to see whether

it acted any differently to the oil being applied separately. For

the final test I premixed a batch of oil and grease to see whether

it acted any differently to the oil being applied separately.

As you might expect there's instant coverage along the entire length

of the barrel - and on operating the key it's immediately apparent

that some of the bubbles of oil that were held in suspension have

been forced together by the pumping action of the barrel and are

now flowing back and forth as the key is pressed down and released.

You can see a large bubble of oil in the centre of the barrel, but

what's especially interesting is that as the bubble moves there

appears to be a certain amount of reintegration at the boundary

edge - and I think it's fair to assume that rather more of this

is going on where the pressure is highest...which is directly beneath

the key arms.

Note that the dark line across the key arm has gone. In fact it's

still there, but now it's filled with the dyed oil - and the stiffness

of the grease surrounding this wear point seems to be regulating

the back-and-forth flow of the oil, making it less easy for the

oil to completely flow away. As such it acts rather like a sump

- maintaining a supply of oil in the area where it's most required.

This, it has to be said, is a very significant feature.

So what does it all mean? Well, It means lots of good things.

From the experiments carried out earlier in the article we know

that the drawbacks of using grease are that it doesn't readily flow

back into the areas where it was pushed away from, and that although

it's more tenacious (it doesn't dribble away) than oil it comes

at the price of adding drag to the action. You can mitigate this

to a degree by using thinner grease but you'll still never achieve

the fluidity of oil.

Oil, on the other hand, has excellent flow characteristics but isn't

so good at 'hanging on in there' - and very readily flows away from

the areas it's most needed when the key is operated.

The solution has always been to select a grade of oil or grease

that provides the best compromise, which typically means a light

grease or a heavy oil. There are some systems where it's possible

to mix the lubricants, but you're still only altering the viscosity

of what's essentially a single product. In other words it's a 'monograde'

solution.

The properties of the silicone grease/synthetic oil mix are such

that it's a 'multigrade' solution. The oil will never fully combine

with the grease, but will happily integrate with it on a temporary

basis - and neither will they react with each other to form an undesirable

compound. It gives you all the staying power of grease and all of

the speed of oil. And it remains viable over a wide range of temperatures.

It also means being able to use a grease that's far stiffer than

you'd normally be able to get away with - and this has significant

benefits in terms of reducing the mechanical noise from the action.

In terms of application you have a couple of choices. You can premix

the lubricants and apply them as a normal grease. The ratio can

be variable, but a 50/50 mix is a good place to start.

Or you can mix on application. This is my preferred method as it

allows you to gauge and adjust the drag while you're fitting the

keys. I tend to grease the rod screw up along its length, insert

it into the key barrel and work it back and forth a little to ensure

the bore of the barrel is fully coated. I then remove the rod and

give it a quick wipe off with a bit of clean kitchen roll. I then

apply oil to the rod and reinsert it into the barrel.

This is typically on a barrel with very close tolerances. On a horn

where there's a bit of wear and tear I'll often skip wiping the

grease off the rod and simply add the oil.

The advantage of doing it this way is that you can tailor the mix

to suit the key. Thus you might favour more grease on heavily-sprung

keys (such as the palm keys) and more oil on the ones that need

to be more sprightly (such as the G# cup key or the octave mech).

If you get it wrong or simply want to tweak the feel of a key, just

pull the rod screw out, give it a wipe and add more oil/grease depending

on which way you want to go.

In addition to the bench tests I've been carrying out 'field tests'

with the multigrade method and so far I haven't come across any

drawbacks, and have a sneaky feeling that this might well be a perfect

solution for lubricating the keywork.

Update June 2019:

I've

been experimenting with grease/oil combinations with a view to looking

for any unexpected or unwanted effects, but as yet I haven't found

any of significance. However, I have found that non-synthetic (i.e.

mineral) oils tend to form a more stable emulsion. I've

been experimenting with grease/oil combinations with a view to looking

for any unexpected or unwanted effects, but as yet I haven't found

any of significance. However, I have found that non-synthetic (i.e.

mineral) oils tend to form a more stable emulsion.

The shot on the right shows a pair of test samples, with the sample

on the left being synthetic oil and silicone grease, and the one

on the right mineral oil (standard gear oil) and silicone grease.

Upon mixing the samples they both formed the familiar milky solution

which slowly separated when left to stand - but the rate at which

this happened was far slower with the mineral oil mix. This shot

was taken after several months of standing, and you can see that

while there's a distinct boundary line between the grease and the

synthetic oil, the boundary line of the mineral oil sample is much

less well defined. It's also the case that while the fully synthetic

sample achieved visible separation in less than an hour, it took

considerable longer for the mineral sample to show signs of separation.

The samples were tested at various temperatures, but the end results

remained the same.

It's possible to draw a few conclusions from this test, the first

of which is that silicone grease is unlikely to combine unpredictably

with whatever lubricant that may be present in the key barrels.

It's also clear that the slower rate of separation of the mineral

oil mix will, due to the mixing effect of the oil being pumped through

the key barrels, tend towards acting more like a heavy oil/light

grease - which reduces its effectiveness as a multigrade solution.

Field testing continues, but no adverse effects have come to light

thus far.

|

I

dug out an old 'beater' sax, cut the key arms off the G# key and

replaced the barrel with a stiff acrylic tube. I then made and fitted

a rod screw, and just to make it a tough test I made sure the rod

screw was a very snug fit. I glued the key arms in place and fitted

a spring - with no spring cradle on the key I simply ran the spring

over the top of the link arm (which rests on the G# key cup arm).

I

dug out an old 'beater' sax, cut the key arms off the G# key and

replaced the barrel with a stiff acrylic tube. I then made and fitted

a rod screw, and just to make it a tough test I made sure the rod

screw was a very snug fit. I glued the key arms in place and fitted

a spring - with no spring cradle on the key I simply ran the spring

over the top of the link arm (which rests on the G# key cup arm).

This

phenomenon was more evident with a thinner oil. Here I've mixed

some black oil with a bit of typically thin shop-bought key oil.

The pumping action was rather more rapid and widespread, and there

was far less evidence of the pooling effect at the end of the key

barrels. In short, the oil was simply being ejected from the key

barrel.

This

phenomenon was more evident with a thinner oil. Here I've mixed

some black oil with a bit of typically thin shop-bought key oil.

The pumping action was rather more rapid and widespread, and there

was far less evidence of the pooling effect at the end of the key

barrels. In short, the oil was simply being ejected from the key

barrel. The

grease is bog-standard high tack (HT) silicone grease and the oil

is 75W90 synthetic gear oil (as shown in the article on

The

grease is bog-standard high tack (HT) silicone grease and the oil

is 75W90 synthetic gear oil (as shown in the article on  Emulsions

have a tendency to separate over a period of time - hence the 'stir

well before use' warning on pot of emulsion paint and the 'shake

well before use' on a bottle of salad dressing - so I left the tube

standing, to see whether or not the lubes would separate and, if

so, how quickly.

Emulsions

have a tendency to separate over a period of time - hence the 'stir

well before use' warning on pot of emulsion paint and the 'shake

well before use' on a bottle of salad dressing - so I left the tube

standing, to see whether or not the lubes would separate and, if

so, how quickly. I

began by testing how the silicone grease performs on its own inside

a key barrel.

I

began by testing how the silicone grease performs on its own inside

a key barrel. The

result is very encouraging. With only a few presses of the key you

can see that the oil and been drawn around a quarter of the way

into the barrel, and is just starting to make its way past the first

key arm. And it's travelling uphill.

The

result is very encouraging. With only a few presses of the key you

can see that the oil and been drawn around a quarter of the way

into the barrel, and is just starting to make its way past the first

key arm. And it's travelling uphill. For

the final test I premixed a batch of oil and grease to see whether

it acted any differently to the oil being applied separately.

For

the final test I premixed a batch of oil and grease to see whether

it acted any differently to the oil being applied separately. I've

been experimenting with grease/oil combinations with a view to looking

for any unexpected or unwanted effects, but as yet I haven't found

any of significance. However, I have found that non-synthetic (i.e.

mineral) oils tend to form a more stable emulsion.

I've

been experimenting with grease/oil combinations with a view to looking

for any unexpected or unwanted effects, but as yet I haven't found

any of significance. However, I have found that non-synthetic (i.e.

mineral) oils tend to form a more stable emulsion.